Reactors (EX-proof)

Personal information

Name:

Business Development

Email:jeroen.degraeve@bbeu.org

Service Provider:Read More

Type of Collaboration:Fee paying basisFunded collaborative projectJoint venturesNegotiable

What "non-technical" services relevant to scale-up does your organisation offer?:Technoeconomic Assessment

ASSET INFORMATION

Asset Information:

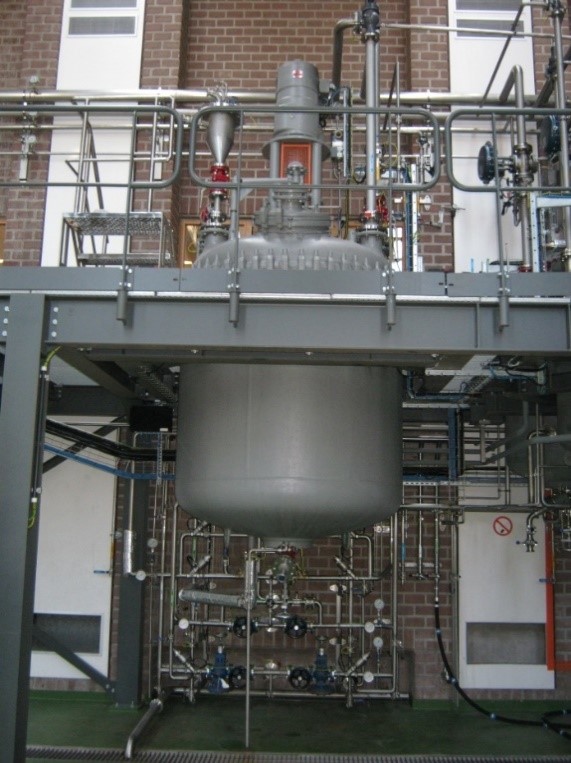

Reactors (EX-proof)

Raw Material:

Biomass - any

Process Stage:

Separation Technologies

Technology:

Biocatalytic conversions, Chemical conversions, Chemical or enzymatic pre-treatment, Chromatography, Crystallisation and precipitation, Evaporation, Extraction, Flocculation, Heterogeneous catalysis, Hydrolysis, Thermal or pressure pretreatment

Technology Area:

Chemical processing

Scale:

Semi Pilot, Pilot, Demonstration

Additional Technical Information:

ATEX compliant installation and expertise for chemical processes:

Solvent evaporation and condensation

Zoning of the operational area to ATEX zone 2

Explosion protection on all electrical equipment: ExII2G T3

N2 inertisation and blanketing

Pressure proof from -1 to 9 bar

Types of processes:

Chemical synthesis reactions

Chemical conversion reactions

Chemical hydrolysis

Extractions

Green Chemistry equipment overview:

Glass lined, pressure proof and corrosion resistant reactors, coupled to a condenser and vacuum pump.

Properties:

Pressures up to 9 bar

Temperatures up to 200°C.

Vacuum down to 20 mbara

Reactor volumes (ATEX):

1 x 5400 L

1 x 1000 L

1 x 500 L

1 x 85 L

1 x 20 L

1 x 5 L

1 x 2 L

1 x 0.5 L

Auxiliary equipment (ATEX):

Green Chemistry examples:

Functionalisation of biopolymers and oligosaccharides

Esterification of fatty acids

Synthesis of oleochemicals

Chemical synthesis of biosurfactants

…

More info on http://www.bbeu.org/pilotplant/technologies/green-chemistry/

Solvent evaporation and condensation

Zoning of the operational area to ATEX zone 2

Explosion protection on all electrical equipment: ExII2G T3

N2 inertisation and blanketing

Pressure proof from -1 to 9 bar

Types of processes:

Chemical synthesis reactions

Chemical conversion reactions

Chemical hydrolysis

Extractions

Green Chemistry equipment overview:

Glass lined, pressure proof and corrosion resistant reactors, coupled to a condenser and vacuum pump.

Properties:

Pressures up to 9 bar

Temperatures up to 200°C.

Vacuum down to 20 mbara

Reactor volumes (ATEX):

1 x 5400 L

1 x 1000 L

1 x 500 L

1 x 85 L

1 x 20 L

1 x 5 L

1 x 2 L

1 x 0.5 L

Auxiliary equipment (ATEX):

Green Chemistry examples:

Functionalisation of biopolymers and oligosaccharides

Esterification of fatty acids

Synthesis of oleochemicals

Chemical synthesis of biosurfactants

…

More info on http://www.bbeu.org/pilotplant/technologies/green-chemistry/

Address : Rodenhuizekaai 19042 BE